Exposed Fastener Systems

Storm resistant strength with cost-effective affordability

Exposed fastener Benefits

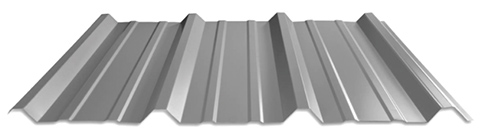

PBR roof & wall panel

features & benefits

26, 24 and 22 Tru-Gauge™ and .032” Aluminum

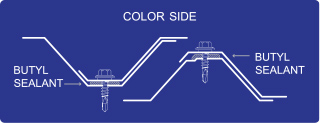

1:12 minimum pitch recommended when installed with butyl sealant

Custom lengths 1’ to 45’ (For longer length panels, please inquire)

Long length flashings available up to 20’ 11”

Standard trim, custom trim and accessory packages available

Color matched neoprene washered screws Roof and Vertical or Horizontal Wall application

Perforated options available (please inquire)

Fiberglass & Polycarbonate panels available to match profile

Manufactured in California

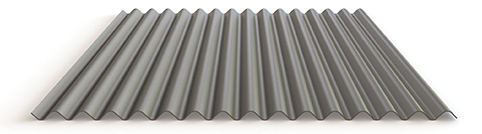

Classic 7/8” Corrugated™ roof & wall panel

features & benefits

24 and 22 Tru-Gauge™ and .032” and .040” Aluminum

1:12 minimum pitch recommended when installed with butyl sealant

Custom lengths 1’ to 45’ (For longer length panels, please inquire)

Long length flashings available up to 20’ 11”

Standard trim, custom trim and accessory packages available

Color matched neoprene washered screws

Roof and Vertical or Horizontal Wall application

Fiberglass panels available to match profile

Manufactured in Riverside CA

An economical, structural, exposed fastener metal roof and wall panel. Deep corrugations allow for aesthetically pleasing shadow lines, making it an excellent choice for siding applications as well.

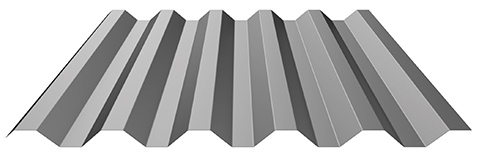

HR-34™ roof & wall panel

features & benefits

26, 24 and 22 Tru-Gauge™ and .032” Aluminum

Custom 20 & 18 Tru-Gauge™ and .040” Aluminum (please inquire)

1:12 minimum pitch recommended when installed with butyl sealant

Custom lengths 1’ to 45’ (For longer length panels, please inquire)

Long length flashings available up to 20’ 11”

Standard trim, custom trim and accessory packages available

Color matched neoprene washered screws

Roof and Vertical or Horizontal Wall application

Manufactured in Riverside CA

PBR, Classic Corrugated, & HR-34 TESTING

Aside from all three of our panels being made in California they all have the same resistance to the elements in roof and wall applications.

ICC-ESR #5045 & #5046 with CBC-CRC Supplement

Code compliance UL Evaluation Report UL ER #25913-01. Construction No. 137, 244

UL 580 Class 90 – Wind Uplift

UL 790 Class A (ASTM E108) – Fire rated

UL 2218 Class 4 – Impact (hail) rated

ASTM E1680 – Air infiltration (roof)

ASTM E1646 – Water infiltration (roof)

ASTM E1592 – Negative structural uniform static air pressure

ASTM E330 – Positive structural uniform static air pressure

ASTM E331 – Water infiltration (wall)

ASTM E283 – Air infiltration (wall)

ASTM A653/A924 – G90 Galvanized

ASTM A792 – Zincalume/Galvalume AZ-50/55

ASTM B209 – Aluminum Substrate